Waikato State Highway maintenance programme – summer season

The Waikato region is benefiting from the national funding injection of over $2 billion for pothole prevention and maintenance, with a significant volume of road renewals planned in this region over the next 3 summers.

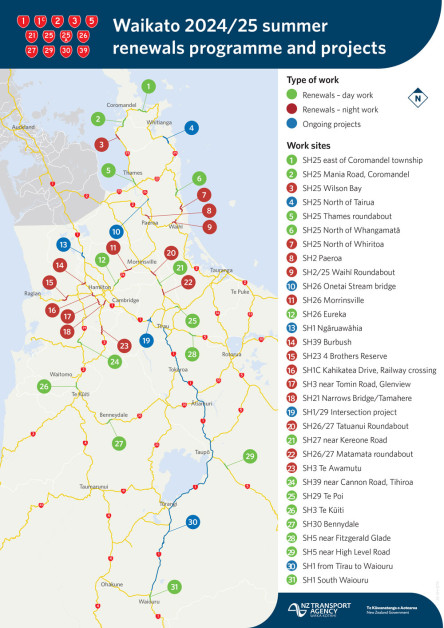

In total over 180 lane kilometres of road will either be rebuilt or resealed, with a substantial portion of this planned to take place over the next 6 months.

We are minimising disruption by thinking differently and challenging our suppliers to be as efficient and effective as possible. This includes using methods such as road closures to allow suppliers to get in and complete work in a quicker and safer way, and with fewer road cones.

This approach is already in use on the State Highway 1 (SH1) Tīrau to Waiouru maintenance project. The stage between Tīrau and Putāruru has already been completed and the next stage between Tokoroa to Kinleith/Upper Ātiamuri started this week.

Highlights of the programme include significant resealing around the Coromandel Peninsula, a number of asphalt resurfacing sites at the southern end of Hamilton along with the major rebuild programme on SH1 between Tīrau and Waiouru.

Renewal accrual in the Waikato this summer(external link)

Upcoming works for Friday 27 June - Friday 11 July:

Waikato & Bay of Plenty state highway works [PDF, 376 KB]

How to be safe around roadworks

Our contractors carry out the maintenance work across Northland on behalf of NZTA, so you will likely see their crews when you’re out travelling through the region.

Kia Tupato Ki Nga Kaimahi – please watch out for any road workers. We care about our team and believe everyone has the right to return home to their whanau at the end of the day.

Always reduce your speed, adhere to the temporary speed limits and follow the traffic management directions at our work sites.

It’s important to slow down through newly sealed sections of road because small chips can be flicked up from the road surface and damage vehicles – especially windscreens. That’s why we often keep temporary speed limits in place even after it looks like the work has been completed. As well as safety, the temporary speed limit also helps ensure the quality of the reseal. Travelling at the posted temporary speed limit allows for the chips to be embedded into the road surface and for them to remain in place as the seal cures.

Please be patient with our crews as they set up and pack down work sites including placing or removing cones and signage. Overtaking these working vehicles can be dangerous to our teams on the trucks but also to vehicles travelling in the opposite direction.

If you have any concerns or require information about works in your area call 0800 4 HIGHWAYS (0800 444 449).

Tips for driving on freshly laid chipseal

Watch our video with advice for driving on freshly laid chipseal

Frequently asked questions

View our highway maintenance frequently asked questions(external link)